Our TECHNOLOGY

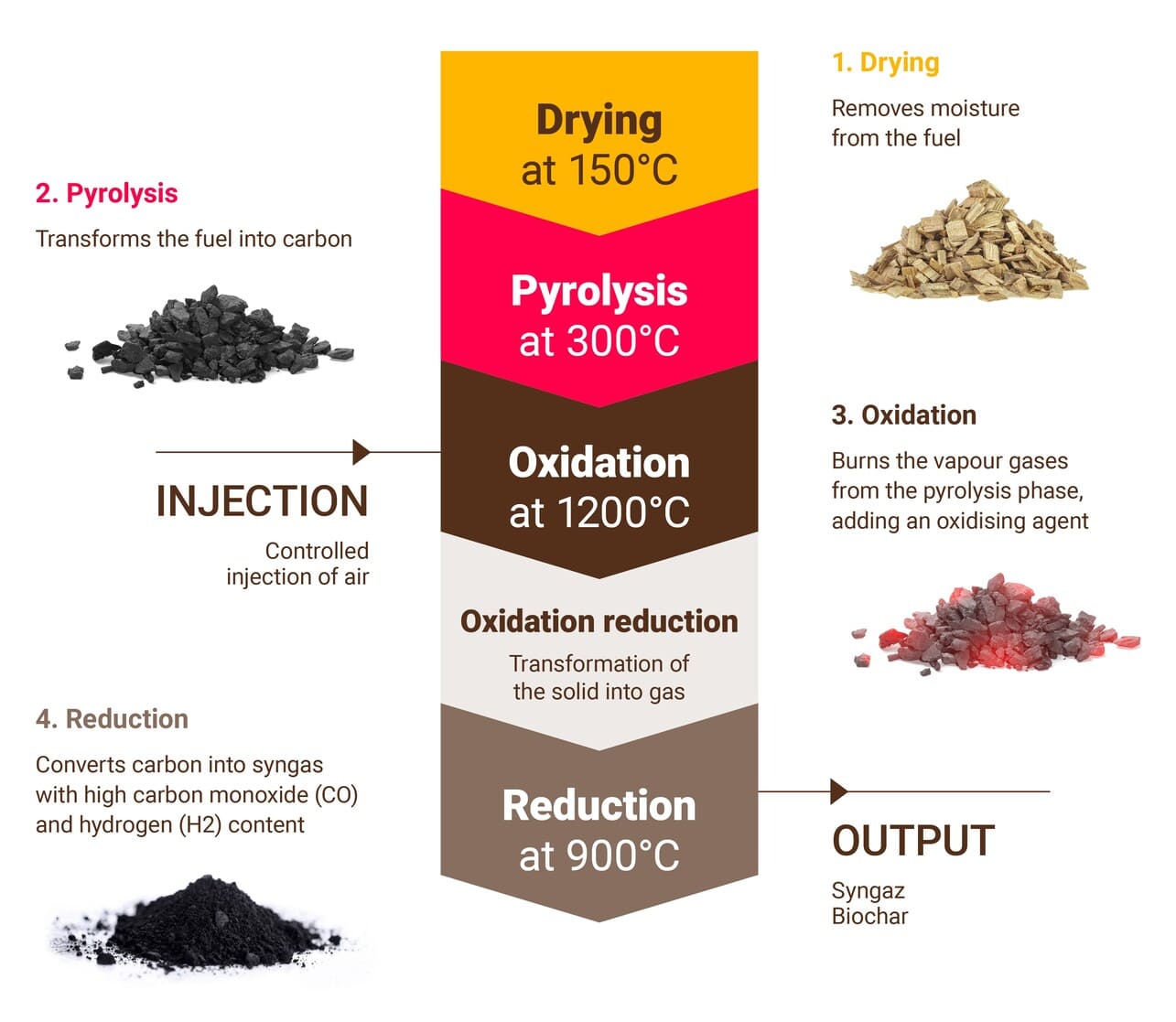

Naoden uses gasification, a thermochemical process that converts solid fuels into a fuel called synthesis gas (syngas), which contains hydrogen and methane, among other things.

GASIFICATION

Gasification is a reactive process with very low inertia. It enables the production of compact solutions with low atmospheric emissions. These technical choices create robust, modular solutions.

WASTE WATER TREATMENT

Naoden has designed a high temperature filtration system specifically adapted to its gasification solutions. Ceramic candles are used to filter the syngas from all particles.

This step is essential in converting the gas into energy while avoiding any risk of clogging the engine or burner.

Naoden is currently developing a new gas purification system (washing). This stage will reduce or even eliminate the various pollutants contained in the gas. This will increase the diversity of recoverable inputs.

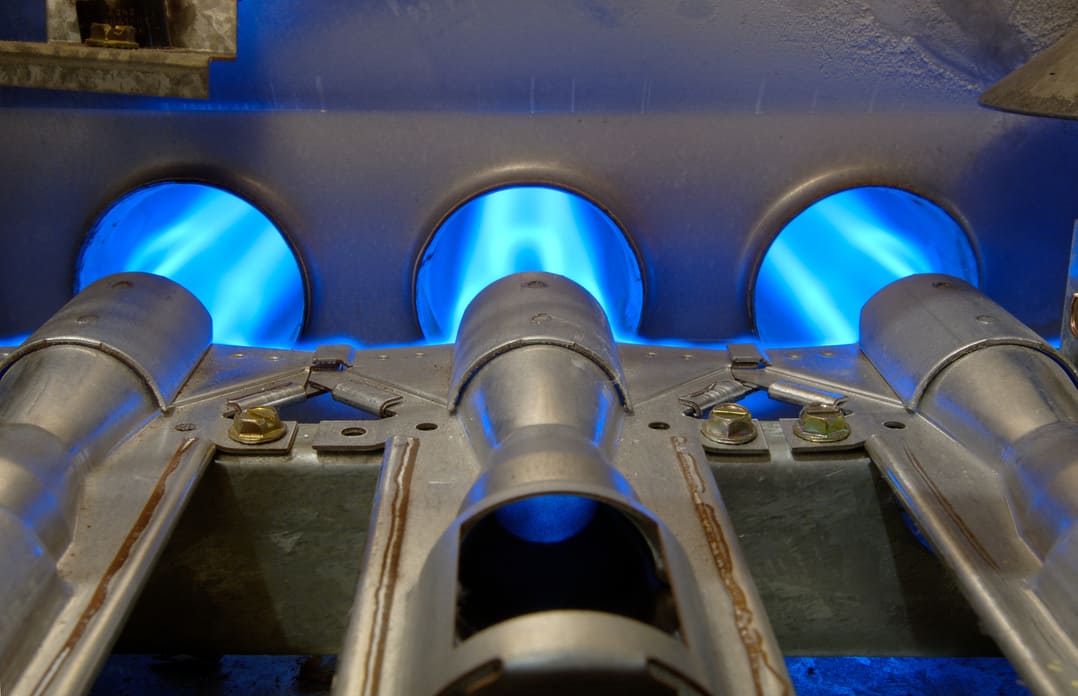

THE THERMAL PROCESS

Syngas can be recovered in a burner to replace or co-combust with a fossil fuel (natural gas, propane). This principle of heat production is central to the Nobilis solution.

The combustion gases from the burner can be used directly as a heat source (dryers, ovens, boilers), or fed into an exchanger to produce hot air.

Naoden is currently designing a dual-fuel burner suitable for different types of processes (steam, hot water, superheated oil, etc.).

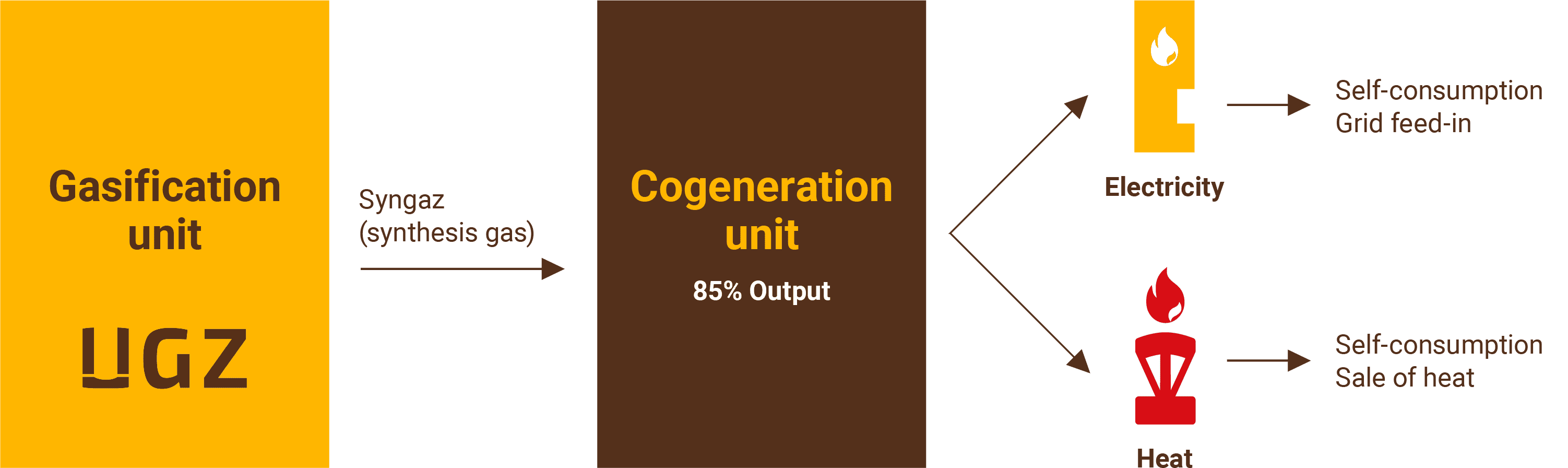

CHP (Combined Heat & Power)

The CHP principle involves the simultaneous production of heat and electricity. This principle is the basis of the Imperium solution.

Energy production breaks down as follows: one-third electricity, two-thirds heat.

Heat is produced in the form of hot water, available under different systems.

NEW GREEN GASES

Naoden is studying the potential of producing new secondary gases like synthetic methane (Biogaz)and hydrogen (H2).

They have many possible uses, including grid-feeding, mobility and even in processes.