F.A.Q.

Fuel

What is the moisture content of the fuels?

We recommend a moisture content of less than 25% (M15-M30).

Above this level, we offer drying solutions.

Include CIBE link

What is the granulometry of the fuels?

The fuels recovered by Naoden solutions are graded P45-P63 with a maximum length of 100 mm.

What are the types of fuel?

The following fuels have already been tested and qualified by Naoden:

– Grade A Wood

– Grade B Wood

– Cardboard

– Green waste (branches, small wood fragments)

– Fruit stones

We are looking for ways to develop fuels and can carry out tests on our test platform.

How much fuel is needed for one machine?

A Naoden unit consumes about 600 metric tons of fuel per year.

Ash

What is the percentage of ash?

The percentage of ash varies according to the fuel used. Overall, ash represents 5% of the fuel by mass.

What is the carbon content of the ash?

The carbon content is around 60%.

How is the ash managed?

Depending on the type of fuel, the ash can be used for spreading or biochar (grade A wood) or sent to a treatment centre (grade B or other wood).

Modules

What is the space required for the machines?

Each module takes up about 5 m² on the ground and a complete plant stands within a platform of about 100 m².

How long does it take to set up a plant on site?

A Naoden power plant can be assembled in 5 days, excluding network connections.

What are the production times?

Production times vary from 3 to 6 months depending on the project context.

Is civil engineering required?

Our modules can be placed outside. Only a slab is required.

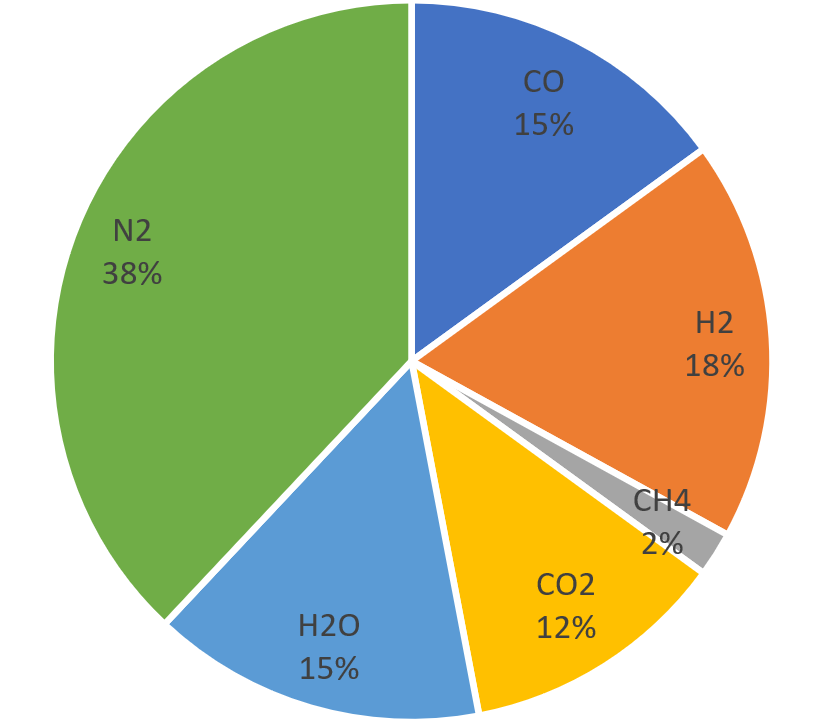

What is the composition of syngas?

What is the output of a machine?

The overall output is 86%, breaking down as:

– Thermal output: 56%

– Electrical output: 30%

Are Naoden units noisy?

The units are not noisy. They do not generate any noise pollution.

Where does production take place?

The products are designed, assembled and installed by Naoden. 90% of our solutions are produced in the West of France.

What about the availability of spare parts?

As the units are standardised and have a low-tech approach, spare parts can be obtained in a very short time.

What is the life span of the machines?

Each component can be replaced without any availability constraints. In this respect, the units have unlimited use.